DEMOVERSIONS

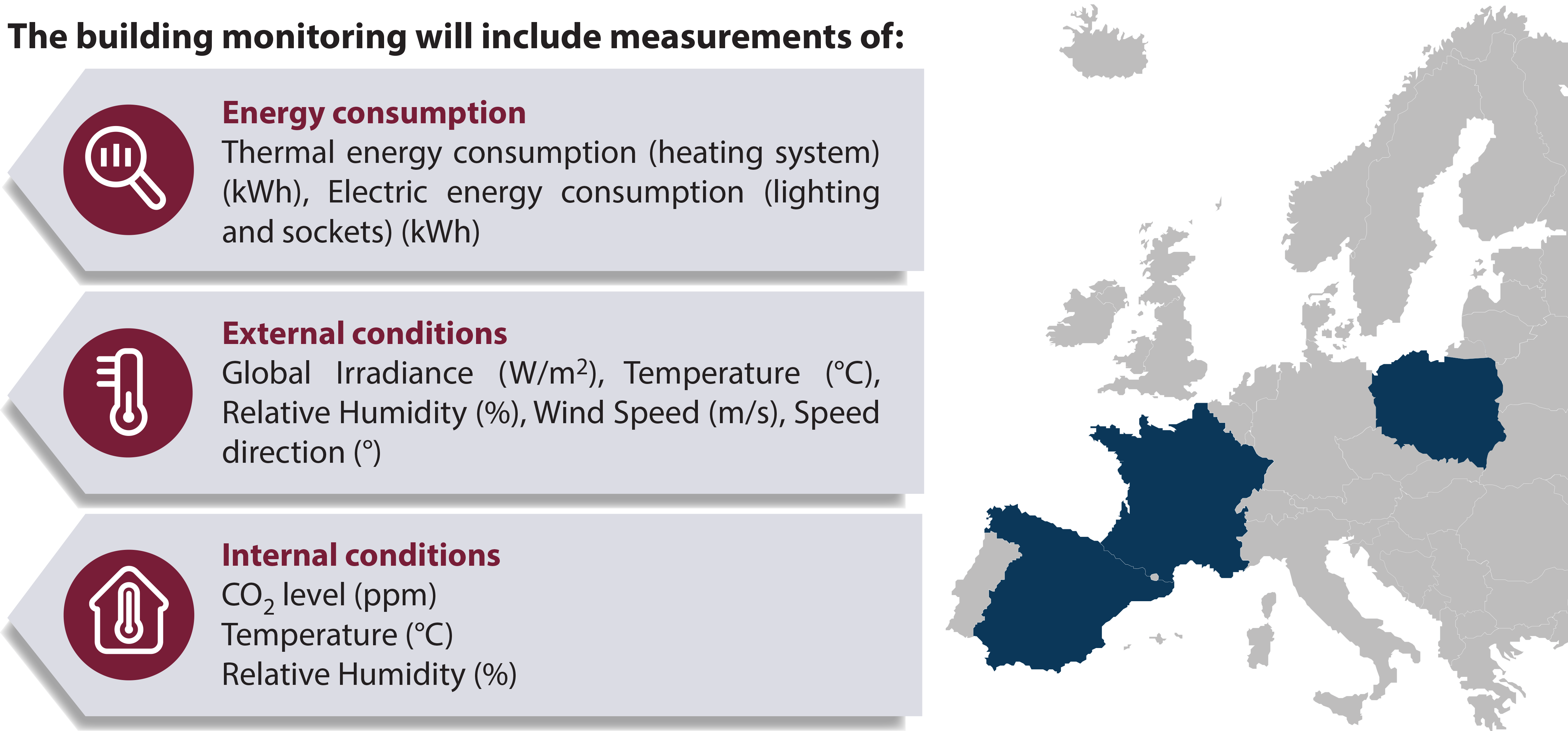

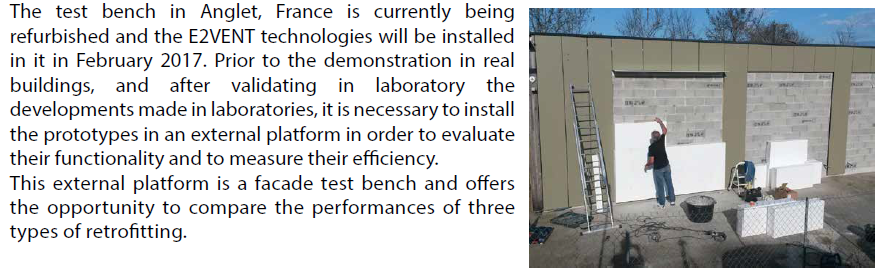

Prototypes performance will be frstly tested on the façade test bench of Nobatek (Anglet, France). Two pilot buildings will be renovated with E2VENT systems - Gdansk (Poland) and Burgos (Spain), in order to test the system in two different climates. To assess the impact of the E2VENT module, the energy performance of the demo buildings is being evaluated before retrofitting. The two buildings that will be retrofitted are monitored during one year.

PILOT BUILDING IN BURGOS

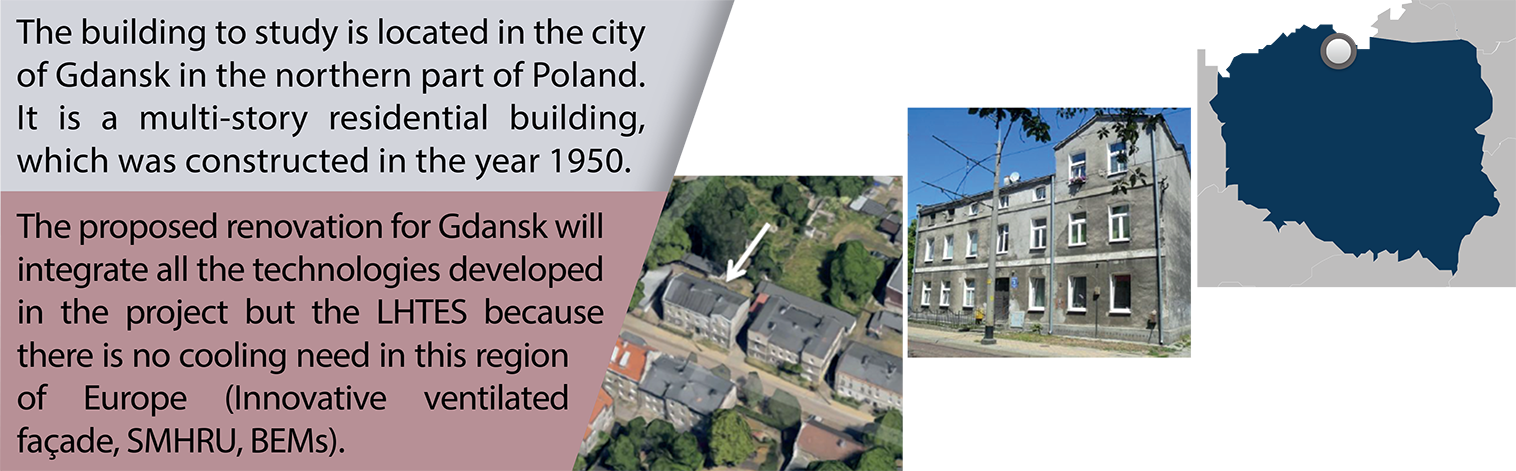

PILOT BUILDING IN GDANSK

TEST BENCH IN AGLET

The E2VENT solution will be compared to:

DEMO-SITE PROGRESS

BURGOS, SPAIN

Entering its final phase, the E2VENT project demonstration on pilots started with the renovation of the first pilot site in Burgos, Spain. The building is in the University of Burgos, partner of the project. It is composed of two rooms (computer lab and classroom) with high internal heat loads which imply a need of air renewal and cooling. The renovation design corresponds to the installation of 3 SMHRU units and 2 LHTES units for a total ventilated façade to be installed of 250 m².

The first step of the renovation consisted of the installation of the HVAC systems on the façade and of the commissioning regarding their correct functioning. This phase started the 30th of October and lasted 3 days. The first day corresponded to the fixation to the wall, the second one to the settings and functioning tests especially regarding piloting, and the third one to commissioning when airflow and noise levels were measured. All partners of the E2VENT consortium joined to participate and assist to the installation of the systems. Their attendance allowed not only to see the finalization of 3 years of development, but also to consider some potential points to be improved for the last design.

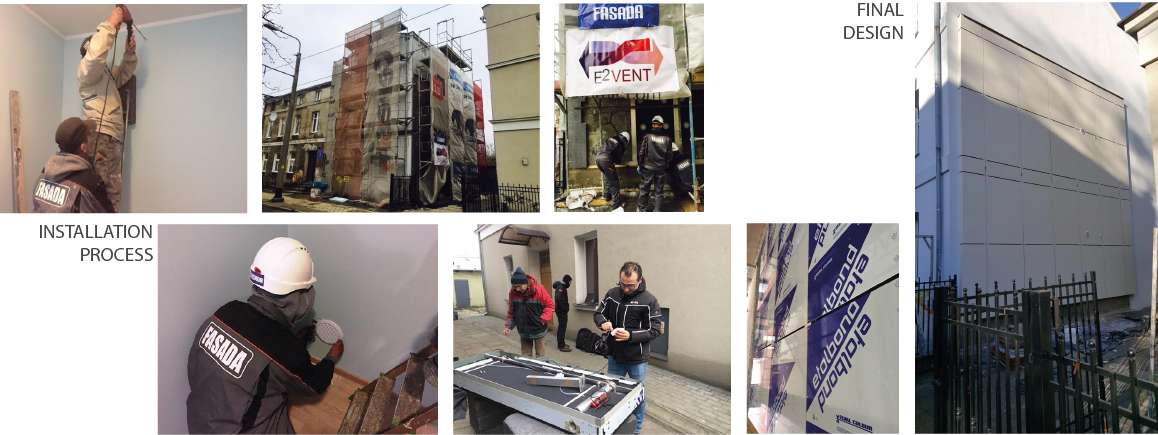

GDANSK, POLAND

The second building, in Gdansk, needed to be renovated because of its low energy performance and low air quality inside the flats that was confirmed by monitoring. E2VENT solutions were demonstrated on two ‑flats. The elements composing the design were two SMHRU (Smart Heat Recovery Unit) allowing air renewal to ensure better indoor air quality while limiting thermal losses thanks to the double ‑flux heat exchanger, two BEM (Building Energy Management) systems, that allow the smart piloting of the HVAC, the ventilated façade (40 m²) of Etalbond panels, fixed on vertical T-proles on VARIO brackets, and ETICS façade (120 m2). The SMHRU and ventilated façades were manufactured in Greece in ELVAL while the BEM system was manufactured and calibrated by CARTIF in Spain. Then all the components were sent directly to Gdansk to FASADA premise.

The first step of the renovation process was marking and drilling of the holes for the installation of SMHRU units in the flats. It was crucial to place the ventilation units in such way that they can work properly and they are fitting the internal furniture location. The works were performed by FASADA in cooperation with other project partners (Tecnalia, Cartif, Nobatec, and Acciona). Important part of the commissioning process were acoustic tests performed, these tests were done in order to find the maximum speed of the ventilators that generates noise that is in agreement with existing acoustic standards. All the tests were performed according to technical standards.